Aggregate Systems

Aggregate Process

In order to make a uniform material that can be utilized for building and landscaping, gravel and other resources like sand and mud go through a procedure called the “gravel aggregate process.” Crushing, sorting, and screening are common practices for producing the appropriate particle size and form from raw materials including rocks, boulders, and more. This method also entails mixing the components together to get a uniform end result. Processing gravel into aggregate is crucial for producing something that is robust, long-lasting, and visually beautiful. As an added bonus, this method guarantees that the resulting blend is both harmless and functional in the desired setting.

Sand Classifier Process

Aggregate sand is separated and classified using the classifier process in industrial sand processing plants. Several screens and other pieces of machinery are used in this operation to categorize the sand by size, shape, and content. Construction, landscaping, water filtration, and other industrial uses are just some of the many end-uses for the sand products manufactured using this method. Whenever it comes to manufacturing high-quality sand products, the AggregateSand Classifier Process is your best option. It’s a method that doesn’t harm the planet or waste materials.

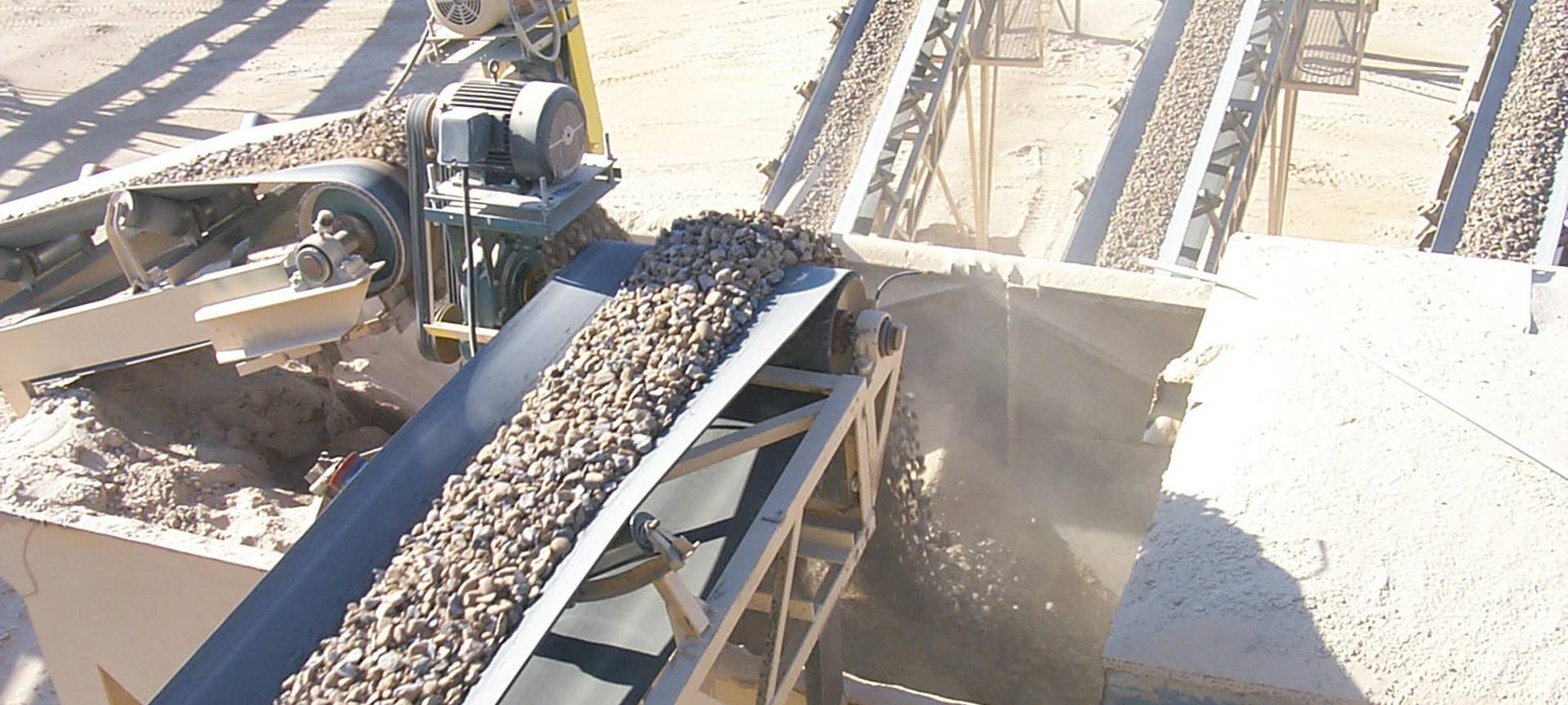

Automatic Stacking

Automatic Aggregate Stacking is a game-changing innovation that ensures the secure and time-saving storage of large items. As a result, it can assist lower the costs of mass production by doing away with the requirement for human labour. Conveyors, stackers, bins, and a controller make up the various components of the system. Materials are transferred from the bin to the stacker via conveyor belt and then piled in a neat and orderly form. The controller keeps tabs on everything and makes sure the stacking is done properly. Because it provides for the safe and effective stacking of heavy objects, the system is widely utilized in the aggregate industry. As an automated system, it also aids in lowering the likelihood of accidents.

Crusher Diagnostics

In order to diagnose issues with aggregate crushers, a thorough diagnostics tool is required, such as the Aggregate Crusher Diagnostics. With its assistance, you can learn everything there is to know about your system, from its individual parts and their interconnections to the specifics of any problems you may be experiencing. It can aid in determining what went wrong, how to fix the problem, and how to avoid it from happening again through preventative measures. With the guidance of Aggregate Crusher Diagnostics, you can make sure that everything is running smoothly and without incident, that will lead to more output and better overall performance.

Weigh and Loadout

The construction and mining industries rely heavily on the aggregate weigh and loadout process. Loading a truck or other vehicle with a bulk material, such as gravel, sand, or aggregate, includes weighing the material and then transferring it based on the scale’s readings to the vehicle’s load area. This method is employed to verify the integrity of the loaded materials in terms of both mass and composition. As a bonus, it ensures that items are loaded properly and securely and reduces the likelihood of cars being overloaded. Aggregate weigh and loadout is also useful for making sure that the required amount of materials are loaded and that any surplus is unloaded. Automated scales and loadout systems are commonly used to ensure precision and effectiveness in this procedure.

Inventory Control

It is common practice to employ a method called “aggregate inventory control” when dealing with massive stockpiles. Inventory management refers to the process of collecting information on and controlling the overall quantity of goods stored in a company’s various warehouses so that supply can always meet demand. Predicting and planning for the future, keeping track of inventories, and restocking when necessary are all part of this process. Costs are cut, stock-outs are minimized, and client satisfaction is boosted due to aggregate inventory control. It is a crucial aspect of any effective plan for managing the supply chain.

Maintenance Logging

In order to keep tabs on and record all maintenance and repair work, Aggressor uses the user-friendly and comprehensive Maintenance Logging system. Users can record and save data on all maintenance procedures and associated costs, and the system also provides a comprehensive summary of all maintenance activities. In addition, it has in-depth reporting and analysis tools for spotting patterns and gauging the efficiency of upkeep tasks. It is crucial for every company that seeks to boost the efficacy and efficiency of their maintenance operations to implement this system.

Production Reporting

The purpose of Aggregate Production Reporting (APR) is to track and record the sum total of all manufacturing activity within an organization. It’s purpose is twofold: to keep tabs on how much material the company has made, and how productive and efficient that producing aggredate has been. Improvement opportunities and potential problems can both be uncovered using this method. The company will be able to make better decisions about how to allocate its resources and how to boost its overall performance with this data in hand. Companies may improve their productivity and stay ahead of the competition with the help of the data revealed by aggregate production reporting.